By Dick Gorman

Northestern Scale Models Box and Crate Factory

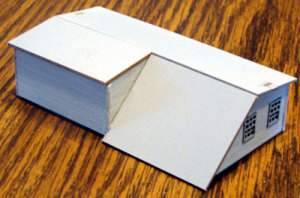

Except for the church, which I think is much too large with those huge windows for N scale, I have liked and enjoyed building all the North Eastern structures on my layout. My latest purchase is the box factory. Here, I will describe how I built it. Right from the start, it looked like the most challenging one, so far (if I exclude the outside stairs on the fire house!!). I gathered the tools I needed: sharp X-acto knife with #11 blade, small file, fine sandpaper, glue (I don’t like using white glue for wood kits because of potential warping so I used Duco Household Cement which is similar to model airplane cement), Walthers Goo, and Micro Kristal Klear (more on this later). As I worked on this off and on over a period of three days, I cannot say exactly how long it took me to complete the building but, I will estimate 5 to 6 hours.

It came in the usual “bubble pack” and inside I found several laser cut sheets, a small pack of detail parts, acetate for the windows, and three pages of fairly good instructions but, they could have been better (comments as we progress). Having learned the hard way (many times!!), I read the instructions carefully. Then, as per my usual routine, I sprayed all the wood parts with cheap Walmart gray primer on both sides as a hedge against possible warping. This is probably unnecessary because of the quality of the wood but, I do use Poly S paint so why take chances? All parts were very neatly cut and required minimal cutting to release them from the sheets.

When the primer was dry, I painted all the parts that needed further color. For the second story and the windows, I thinned some of my wife’s craft paint with a little water so I could brush it on thin, one coat. This way, I could adjust just how white I wanted it to look. The result was a very weathered looking, but well kept, white building in need of a paint job fairly soon. Typical New England. For the first story, I used the same method using Poly S “Earth”. After the paint was dry, I started assembly, following North Eastern’s recommendations, with a few modifications.

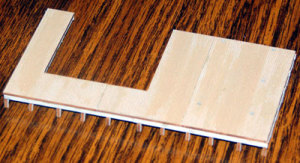

First step is to assemble the base which looks a little complicated but is really straight forward. I left these pieces gray as most of them are unseen. The loading dock I painted “Earth” allowing gray to show through. The instructions indicated the pieces of the “grid” should be cemented together as you build but, the pieces are slotted and fit snugly so I assembled them “dry” and waited until I had most of the platform assembled before applying any cement. This allowed me to ensure the whole assembly was “flat” before cementing. I then glued the platform (deck) pieces to the grid.

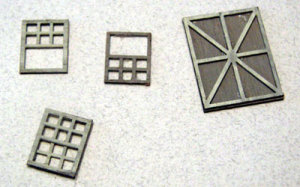

Next step, the windows: Northeastern could have made these directions a littler clearer. NOTE: the pieces that make up the double hung windows are not the same size. One piece (the inner frame) is a little smaller than the outer frame. This allows the inner frame to “snap” into the snug fitting openings in the walls for the windows. I carefully glued the two pieces of each window assembly together. When dry, taking care to orient each window properly (inner piece has panes on the bottom, outer window has frames on the top), I pushed each one into the openings. Then, using Micro Kristal Klear, with a toothpick, I drew small beads of cement on the inside of the window openings and inserted the acetate “glass”. The Micro Kristal Klear dries clear so a little slop or heavy handedness will not show when dry. I assembled the doors and glued four of them to their openings, saving the “notched” one on the end of the second floor for later. They could have been a little clearer about the notched door besides just showing it installed on the end of the second floor. I have no idea why it is different from the others.

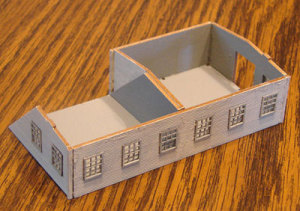

The lower level assembly is quite straight-forward and presented no problems although, mine was just a little too snug when putting it into the opening of the deck so, I had to do a little sanding on the deck opening until the building section would slide in without bending the deck assembly. I then glued the first floor building in place.

The second floor was also a straight-forward procedure, Take care the long wall is right side up when gluing (you needn’t ask why I stress this). When I was satisfied everything was squared with the walls, I glued the roof in place. I recommend starting with part #33 (the notched one), then #34, and, finally, #35. Then, using a straight edge and my #11 bladed knife, I cut out about half of the “rolled roofing” strips provided. Starting at the bottom edge of each roof section, I glued the strips to the roof, horizontally, slightly over-lapping each strip until I got to about 3/32” from the very peak. When I had all the sections done except for the ridge, using a ball-point pen and my straight edge, I “scored” one of the strips length-wise down the middle. I then, carefully, bent the strip into a “V” shape to form the ridge and glued it in place.

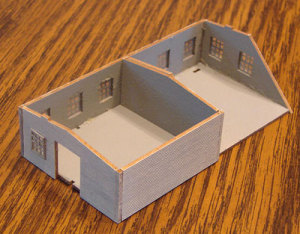

Final assembly looks a little fiddly but, it’s easily done. The directions recommend gluing the second floor to the first but, I deviated a little. Thinking I may, one day, want to disassemble this building for lighting or whatever, I decided to see if my hunch was right in that I could assemble it without glue and have it stay together. There are four “keys” on the tops of two of the first floor walls that fit very snugly into notches in the floor of the second floor assembly. There are also five posts that fit into holes in the deck and upper floor. I first put the posts in their respective holes in the deck (no glue). Then, I started the keys in the first floor “building” into the notches on the bottom of the second floor. I then applied pressure, a little at a time, simultaneously pushing the second floor snug and aligning the posts into their corresponding holes on the bottom of the second floor. Sounds fiddly and confusing but, it works nicely. Just as I suspected, the building is tight. I then glued the last door (the notched one) in place on the end of the second floor using the “Z” strip to show it as a sliding door. I also got the door upside down, according to the drawings.

Following the directions, I assembled the silo and glued it in place. After touching up any spots missing paint, I brushed on some Dull Coat. Spraying would fog the window “glass”.

This was a fun and fairly easy kit to assemble and typical of North Eastern’s usual fine quality. My only criticisms are those I mentioned above about clearer directions concerning the windows and doors.